Paper-based materials—such as cardboard and corrugated cartons—have become ubiquitous in shipping and shopping. Despite plastic’s versatility and low cost, brands and box manufacturers explore raw materials and optimize paper products due to the public’s clamor for sustainable packaging.

If you ship out a high volume of orders weekly or daily, you must choose your paper packaging wisely. Safe shipping leads to memorable unboxing and lower product returns, resulting in customer loyalty and profitability.

This guide on cardboard and corrugated carton boxes aims to compare these two packaging types so you can select the most effective way to package your product or kits.

Distinguishing Cardboard Boxes from Corrugated Carton Boxes

It’s important to know what packaging box suppliers and printers refer to when they discuss cardboard and corrugated carton boxes. They’re folding box types that require assembly, unlike rigid or set-up boxes. Learning more about their individual qualities will help you decide which paper packaging suits your product.

Cardboard packaging (folding carton boxes)

Cardboard or folded carton boxes use heavy paper pulp or thick paper stock. Shoe boxes, cereal boxes, milk cartons, toilet paper rolls, and facial tissue boxes use this material.

Best uses: Cardboard boxes make great secondary packaging or the material surrounding your primary packaging, such as a glass bottle or plastic tub. Moreover, printers find it easier to print intricate designs on cardboard boxes than on corrugated ones due to the flat surface of the former.

You’ll also spend less on cardboard packaging. However, this material is more advisable for lightweight products.

|

Pros of Cardboard Packaging

|

Cons of Cardboard Packaging

|

|

Best for small, thin, and lightweight products

|

Not recommended for shipping due to low compression resistance

|

|

Novel treatment is easier to apply: various shapes, window cutouts, gravure printing (detailed images), and other finishing options

|

Compostable but limited reuse and recycle period (especially boxes with over 40% mylar foil for logos or lining)

|

Corrugated carton packaging

Corrugated carton boxes consist of three-layered sheets: a corrugated (rippled or wavy) medium—or flute—sandwiched by two flat boards or “liners.” Pizza and home appliance brands and their distributors deliver or ship products using this packaging type.

Best uses: Due to their structure, corrugated packaging is ideal for stacking, storage, and shipping. You can also reuse and recycle them more times than cardboard carton boxes.

|

Pros of Corrugated Carton Packaging

|

Cons of Corrugated Carton Packaging

|

|

Safe for heavier or fragile items and packing multiple units due to thicker, sturdier material

|

May require pre-printing or producing labels (litho-lamination) for thicker boards, particularly when designs involve photo-realistic images, foil stamping, or other embellishments.

Thinner boards recommended for direct printing.

|

|

Suitable for stacking and shipping due to strong shock absorption

|

|

|

Can be reused and recycled many times

|

|

Both packaging types are sensitive to moisture. Although corrugated boxes have more layers, you must consider this factor’s possible impact on your products should warehouse or shipping staff leave your box—whether cardboard or corrugated—in an exposed or open area.

Thickness Ranges

Cardboard and corrugated carton packaging differ in density. Suppliers typically use paper stock with a thickness of around 0.5 millimeters to three millimeters for cardboard carton boxes. Meanwhile, corrugated boxes can reach up to around seven millimeters thick.

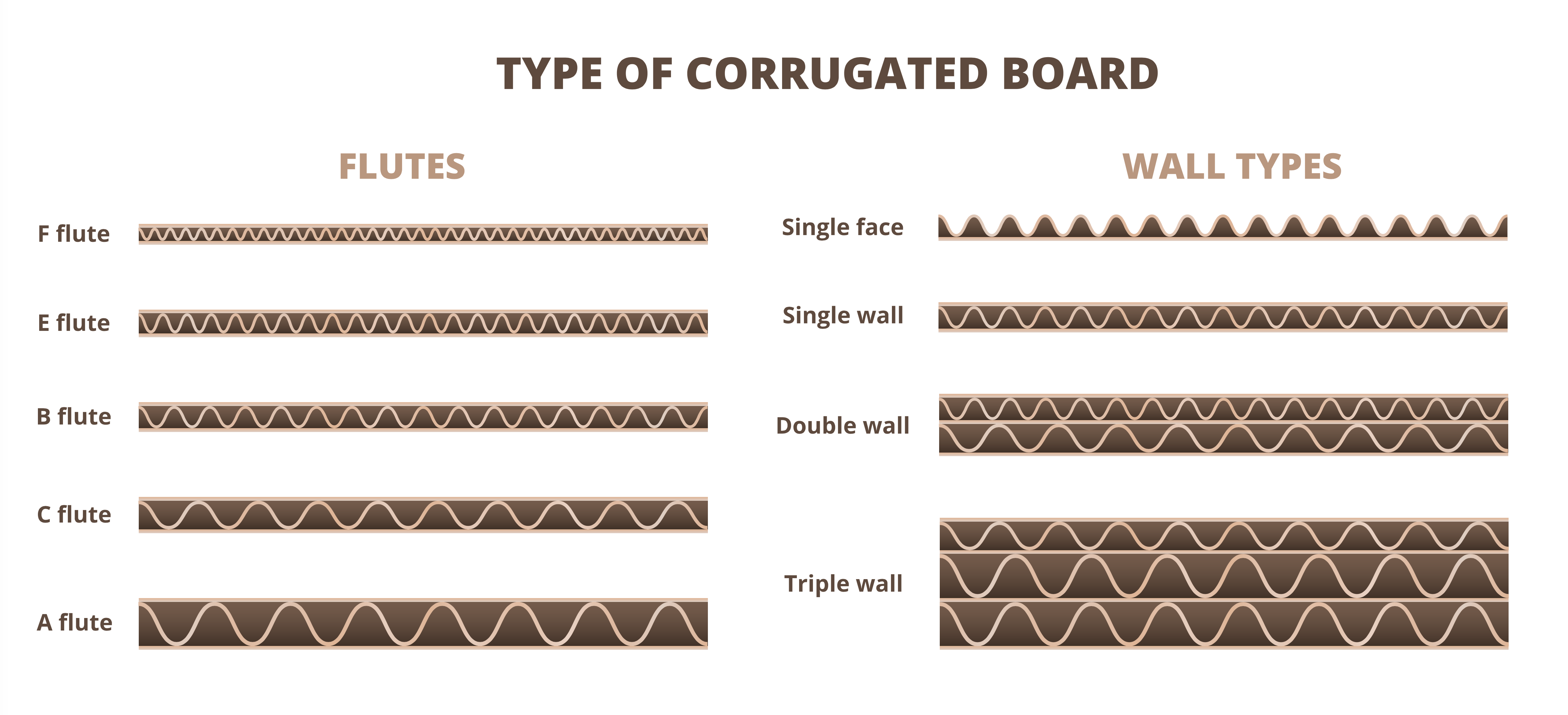

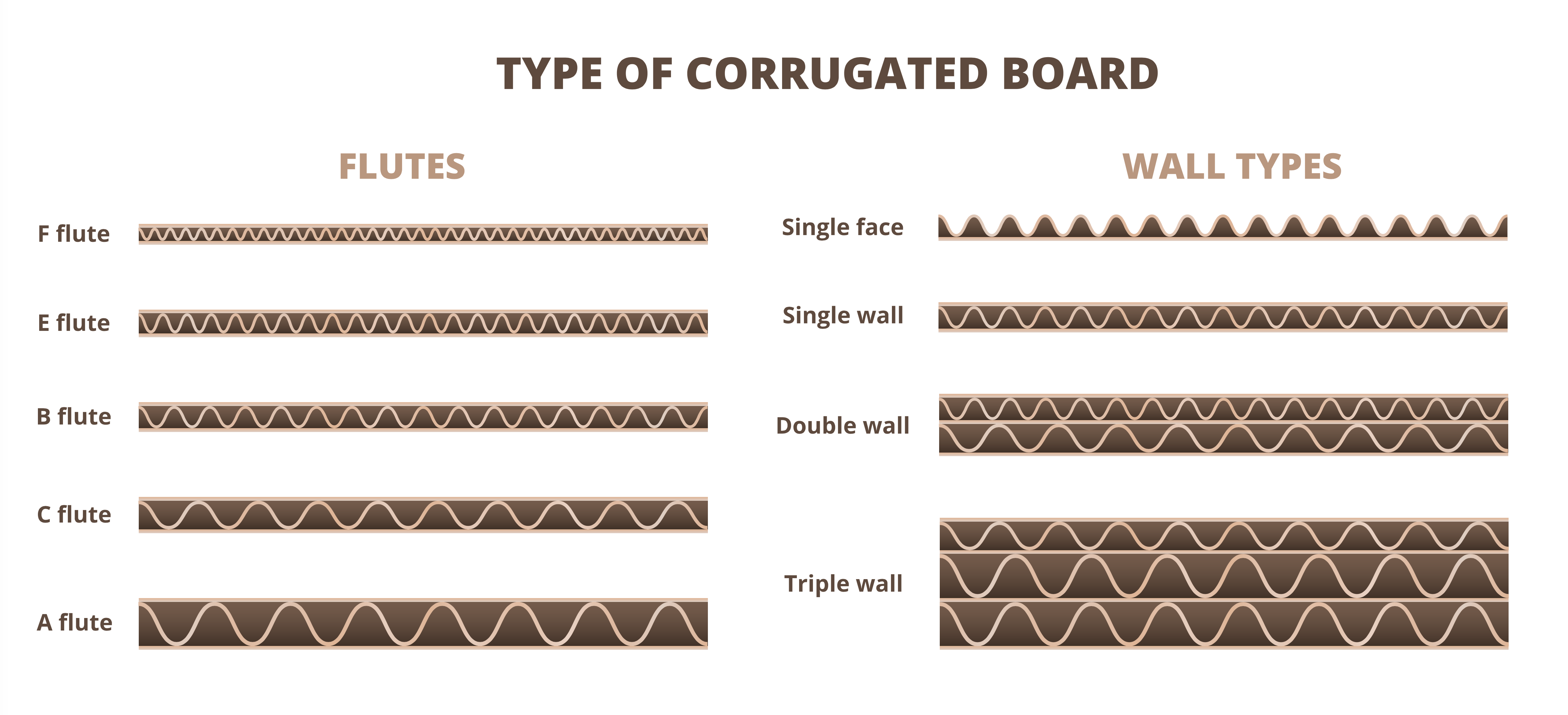

Here are the most common flute sizes (in increasing levels of thickness) and their measurements:

- F flute: 0.6 to 1 millimeter or 1/32″ with 125 to 128 flutes per linear foot

- E flute: 1.5mm or 1/16″ (.0625″) with 90 flutes per linear foot

- C flute: 4mm or 11/64″ with 41 flutes per linear foot

- B flute: 3mm or 1/8″ (0.125″) with 49 flutes per linear foot

- A flute: 5mm or 1/4″ with 36 flutes per linear foot

Most corrugated shipping boxes use the C flute (80%). Meanwhile, E and F flutes are most suitable for high-quality printing applications due to their lower density.

Other flute sizes include:

- D flute: 2mm (.085″)

- S flute: 1.9 to 2.2mm

- EB flute (combines E and B flutes): 3.8mm to 4.3mm or 4.5mm

- BC flute (combines B and C flutes): 6mm to 6.7mm

Furthermore, corrugated carton packaging comes in four board options:

- Single face boards consist of two layers—a liner and a corrugated layer. Their most common use is interior packaging.

- Single wall boards are the most common corrugated box style, featuring two outer liners and a fluted or corrugated layer.

- Double wall boards contain three liners with two corrugated flutes in between them. This extra sturdy construction makes them ideal for industrial use.

- Triple wall boards consist of four liners and three corrugated layers. They can serve as alternatives to wooden crates. This board type is advisable for chemicals and products requiring special handling.

Materials

You can choose from an array of materials for your cardboard and corrugated carton boxes. Let’s look at the available choices for each box type.

Cardboard (Folded Carton) Box

Here are the most common paperboard grades for cardboard packaging:

Solid bleached sulfate (SBS)

SBS is a tear-resistant, white premium-grade paperboard with a naturally occurring clay surface. This paper grade consists of 80% freshly harvested wood chips and 20% recycled materials that underwent chemical processing and bleaching. Available in one (C1S) or two coated (C2S) sides. You’ll find this packaging used for cosmetics, medical products, perishable bakery products, and milk and other dairy products.

Solid unbleached sulfate (SUS) or coated natural Kraft (CNK)

SUS undergoes the same chemical processing as SBS, except that there’s no bleaching, leaving the paperboard’s backside brown. In front, you can use lithography or gravure printing on its smooth, white surface.

Coated recycled board (CRB)

CRBs use 100% recycled paper made from recycled fibers. Its top ply generally contains white fibers with a clay-coated finish, while its backside is gray. This paperboard is a favorite choice for cereal, dry bakery goods like cookies and crackers, laundry detergents, dry food such as pasta, and hardware supplies.

Other paperboard options include:

- Uncoated recycled board (URB) has no coating in the front or on its backside.

- Coated unbleached Kraft (CUK) contains at least 80% virgin fiber.

- Clay-coated news back (CCNB) has a clay-coated front and gray or tan back, depending on the fiber used.

- Thermal mechanical pulp (TMP) features a middle layer of mechanical pulp between two chemical pulp layers. The bleached top layer is coated with pigment, while the translucent back is cream, taking on the color of the middle layer.

Corrugated Box

The most common materials used for the outer and liners (or walls or boards) of a corrugated box are:

Kraft liners

Kraft liners are stiff and strong materials made from 70% to 80% chemical pulp fiber from softwood trees (pine, fir, and spruce). Most outer liners use Kraft paper because of their smooth, finished surface, which allows for easy printing. They’re available in brown, white, bleached, mottled or speckled, and birch-faced.

Test liners

Because test liners use partly or 100% recycled instead of virgin (direct from the source) fibers, they’re not as strong as Kraft liners. Suppliers typically use these as inner liners. Test liners also cost lower than Kraft paper.

Semi-chem (pulp and sulfur) and waste-based (recycled) paper grades

These paper types are the most widely used fluting materials due to their high strength.

Box Styles

Here are some of the most widely used styles for cardboard (folded carton) and corrugated carton boxes.

Cardboard (Folded Carton) Packaging

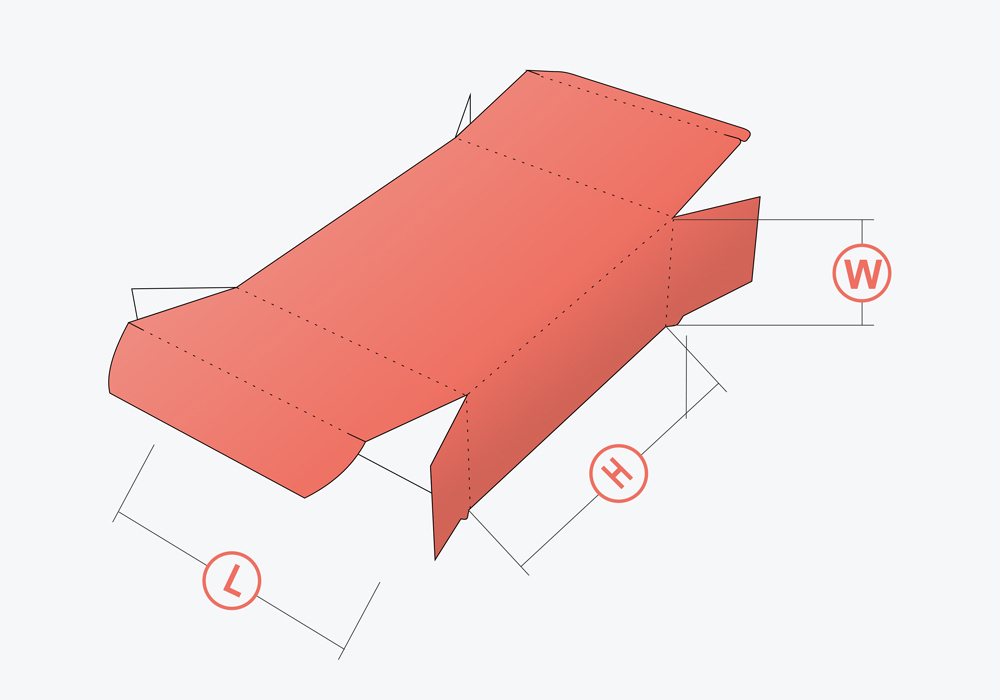

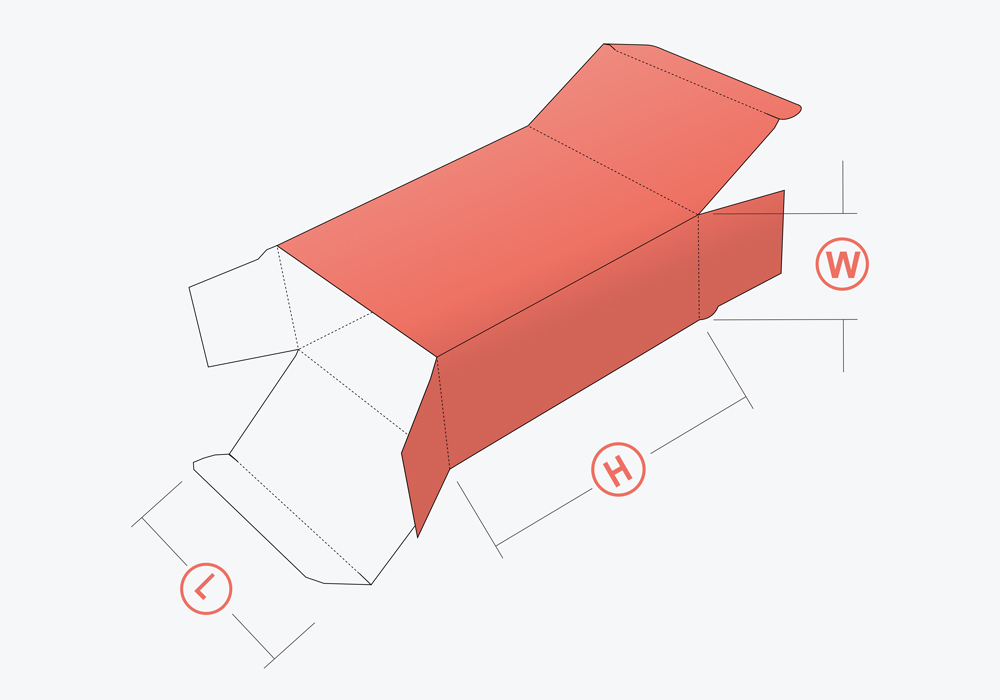

Straight tuck

Straight tuck boxes have top and bottom closures attached to the same side of the box. The closures—which typically feature slit locks near their end flaps—fold from front to back in the same direction.

Lock bottom

Lock bottom or 1-2-3 bottom boxes have a tuck top panel and bottom flaps that push into each other to lock. Its more secure bottom makes the packaging ideal for heavier items (wine, large candles, or electronics). The numeric name of the box refers to the three steps needed to assemble it.

Crash bottom

Crash bottom boxes, also known as auto-lock or auto-bottom boxes, have tuck-top closures and pre-glued bottoms, making them the most secure box type for heavy objects. Its base automatically folds and closes, unlike the lock bottom box, which needs manual assembly.

Reverse tuck

A reverse tuck box’s top and bottom closures are on opposing sides of a box so that they fold in opposite directions.

One-piece tuck top

One-piece tuck-top boxes are similar to mailer boxes, only they’re made of paperboard. They have a top opening with tucking tabs that fold into the bottom of the box. You’ll find many baked goods like donuts sold in this box style.

Two-piece (Simplex or Kwikset tray)

A two-piece box consists of a tray and a lid with double-wall structures. They can come with inserts, making them a highly recommended solution for sweets, luxury products, or kits.

Hanger (hang tab) style

A hanger box is a reverse tuck box with a hanger panel extending from the back, allowing you to hang it on a hook or stand for retail display.

Gable top (handle or carrier box)

Gable top boxes have a crash bottom and a top handle. It’s a popular style for packaging gifts and food.

Pillow style

A pillow box has a curved shape with flap closures on the sides that bend in. They can contain lightweight and small products, such as jewelry, hair accessories, soaps, party favors, or event giveaways.

Corrugated Packaging

Regular slotted container

A regular slotted container box’s top flaps or closures have equal lengths. A gap exists between the inner flaps. However, the outer or lengthwise flaps meet the middle of the box when you fold them in to close.

Center special slotted container

Unlike the regular slotted container, the outer flaps don’t share the same length as the inner flaps, which meet at the center of the box (hence, the name). The “gap-less” closures provide a more level and stable base and top.

Half-slotted container

People often use the half-slotted container for open storage, as it follows the same structure as a regular slotted container except for its top, which has no flaps.

Overlapping slotted container

This box type is like the regular slotted container, but its outer flaps overlap by at least an inch. You can use staples or adhesives for closing securely. This overlap becomes an indispensable feature for boxes with a greater length than width, which creates a wider gap between the inner flaps.

Fully overlapping slotted container

This style is like the regular slotted container, except that the outer flaps’ length is equal to the box’s width and fully overlaps when bent inward to close. The overlapping flaps act as cushioning in case of stacking.

Center special fully overlapping slotted container

This box type combines the features of the center special slotted and the fully overlapping slotted boxes. Its inner flaps meet in the middle—offering a level, “gap-less” base—while the outer flaps overlap.

Telescope box

Telescope boxes have lids that fit snugly by at least two-thirds the depth of their bottom pieces.

Design style container with a cover

This style is like a telescope box, but the lid extends less than two-thirds the depth of the body.

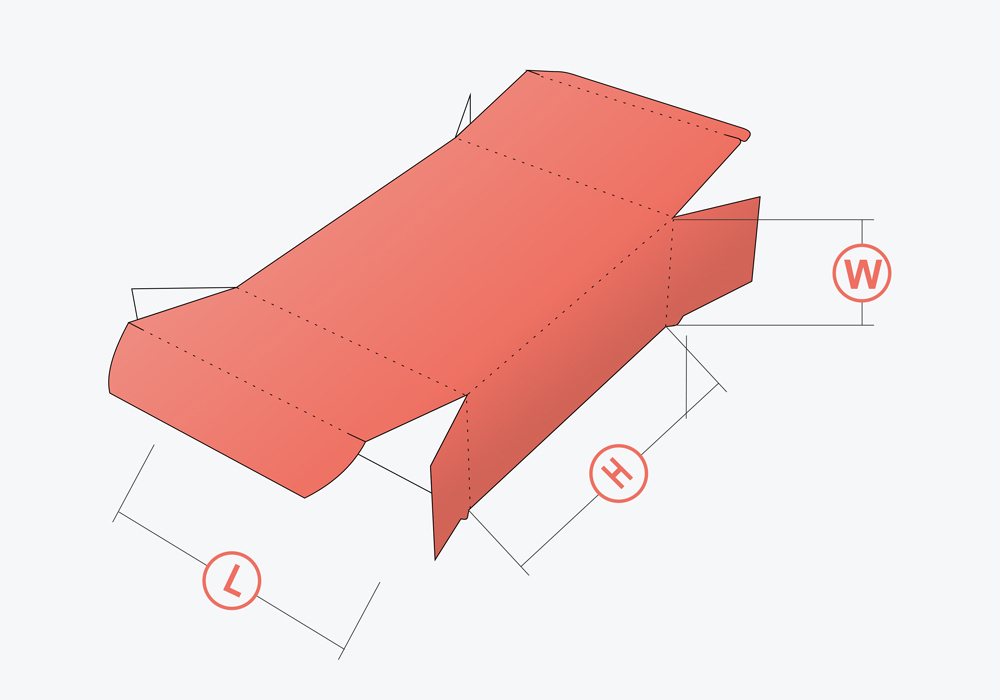

One-piece folder

A one-piece folder is typically one large corrugated sheet that you crease and fold until you get a flat and unbroken base. You can use this packaging for shipping books and printed products.

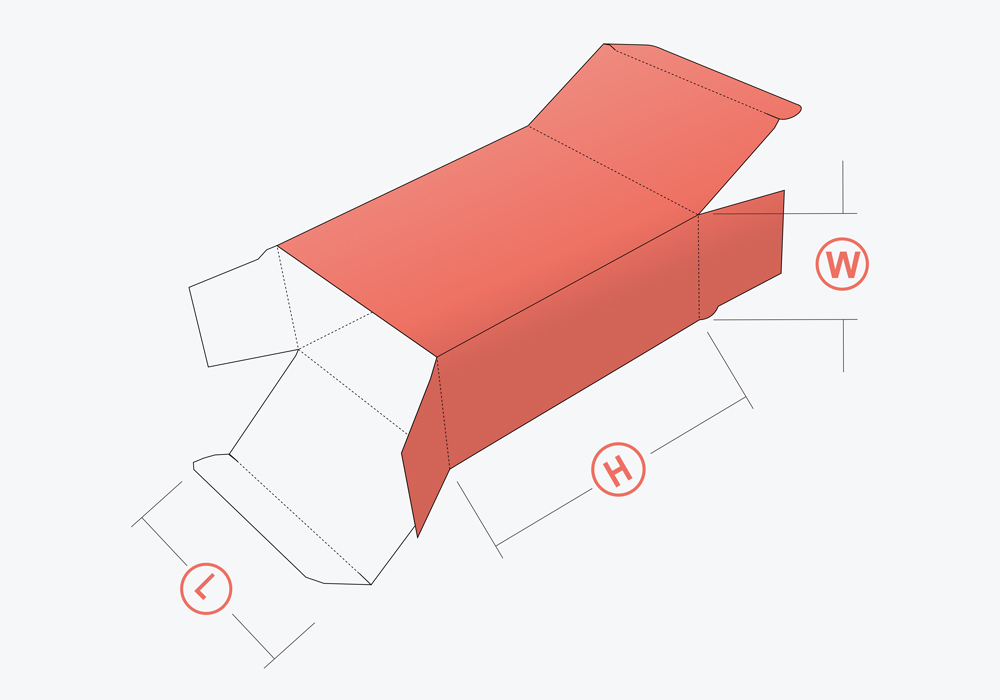

Auto-lock or 1-2-3 bottom container

Auto-lock boxes in corrugated packaging share the same pattern as cardboard or folded carton boxes. Its four die-cut bottom flaps snap into place, folding inwards over one another and then “lock.”

This table shows you the most popular box styles discussed above at a glance:

|

Cardboard (Folded Carton) Box Styles

|

Corrugated Carton Box Styles

|

|

1. Straight tuck

2. Reverse tuck

3. Lock bottom (1-2-3 bottom box)

4. Crash bottom (auto-lock bottom/auto bottom)

5. One-piece tuck top

6. Two-piece (Simplex or Kwikset tray)

7. Hanger (hang tab) style

8. Gable top (handle or carrier box)

9. Pillow style

|

1. Regular slotted container

2. Center special slotted container

3. Half-slotted container

4. Overlapping slotted container

5. Fully overlapping slotted container

6. Center special fully overlapping slotted container

7. Telescope box

8. Design style container with cover

9. One-piece folder

10. Auto-lock or 1-2-3 bottom container

|

Eco-Conscious Preferences Rising

Paper packaging scored the highest in the “Trend Tracker Survey 2023,” whose respondents reached over 10,000 people from 16 nations worldwide—including the US, Europe, South Africa, and South America. Participants rated packaging materials (paper/cardboard, metal, plastic, and glass) according to 15 attributes (physical, visual, and environmental features).

Paper and cardboard received 10 for their compostability (76%), eco-friendliness (55%), and recycling ease (49%). 55% of US-based respondents plan to buy more from companies that stop using plastic for their packaging. Moreover, 47% are considering avoiding stores that don’t actively reduce non-recyclable packaging.

As a result, 75% of the world’s organizations have made “sustainable packaging commitments.” The percentage is higher among consumer goods firms (80%) compared to B2B and industrial companies (66%).

Amid consumer consciousness and robust online sales, industry insiders predict the paper packaging market’s value will hit $3.8 billion by the end of 2023.

Some food for thought: recycled paper makes up over two-thirds of the paper—over 50 million tons—that America uses. Some sources say the amount of paper the US recycles daily can fill boxcars lined up for 15 miles.

Trends in Paper Packaging

Various companies have revised their original box designs to lower their carbon footprint. Discover how businesses are customizing their packaging:

Smaller, lighter box designs

Continental AG, a world leader in automotive parts and tires, has redesigned its timing belt (for vehicle engines) with water pump kits to a smaller size, allowing shippers to transport nearly 70% more boxed kits per pallet.

Meanwhile, German firm Jägermeister has begun using corrugated boxes—replacing its solid board packaging—for shipping its herbal liquor product.

Grass cardboard

Paper and cardboard factories are turning to grass cardboard fibers from nature reserves to make carton packaging materials. Dried grass pellets compose up to 50% of their mixture that also contains recycled or virgin fibers. Factories using grass can save up to three cubic meters of water per ton of cardboard.

Seed or plantable packaging

Plantable packaging does what its name claims it to be. Users can grow the seeds (such as herbs, lettuce, carrot, chamomile, or wildflowers) embedded in the box—typically made of recycled paper. Pangea Organics, a skin and body product line, and Bloom Everlasting Chocolate are two businesses that have adopted plantable packaging.

Compostable film for window boxes

Fresh produce brands, such as SoFruPak, have introduced cardboard trays with lids that have compostable cellulose film coating inside. The plastic substitute works well with cutout windows.

“Self-healing” boxes

Packaging providers have begun working on smart packaging concepts featuring a web of sensors that can alert delivery firms about sustained damage, based on how leaves react to external stimuli. The futuristic material can stretch and thicken itself to repair the damaged spot or any tear after unboxing to ensure their reuse.

Current Challenges Faced by Cardboard and Corrugated Box-Making Firms

Despite dynamic strides in paper and carton recycling, packaging companies face the following challenges:

1. Fluctuating raw material prices

The price of raw materials—paperboard types and adhesives— dictate the rate of production cost.

2. Last-minute orders

Suppliers need high-speed machines to fulfill orders for an additional x number of boxes that clients inform them about at the end of the day.

3. Demand for “no-minimum quantity” projects

Some packaging firms allow customers to determine order volumes to sustain their business.

4. Compatibility between older equipment and new materials

Factories must test new materials on their existing machines to ensure they won’t negatively affect performance.

5. Alternative packaging materials

Carton boxes compete with flexible packaging and molded pulp, which can be more lightweight and versatile in size and shape options.

6. Environmental concerns

The majority of the public considers paper-based packaging as more eco-friendly than plastic. However, producing cardboard requires more water than making plastic. Some sectors have also raised the alarm about food getting contaminated by printing inks, coatings, and paper-bleaching chemicals.

Choose a Packaging Manufacturer with Dual Expertise and Capabilities

When searching for a shipping solution for your product, box printing companies like Refine Packaging can provide support when you’re deciding on a suitable paper-based box type for your brand.

You can view your options right from our Products page. We also customize packaging based on your existing design. Still don’t have a design? No problem. We have seasoned in-house designers and packaging specialists who can walk you through the creation process. They can help you develop a custom box that will suit your product’s supply chain journey, brand identity, and budget. Contact us today to discuss your cardboard or corrugated carton box idea with our team.

.svg)

Share