Don’t you love to shake presents to guess what’s inside?

Chances are, the content will jiggle if the box is much larger than the content, especially if the giver packed it themselves by hand. When the gift is heavy and quiet, we secretly wish it’s a luxury or high-end item. Why? More often than not, brands selling pricier products package them with inserts that hold them steady in the carton container.

If you’re considering packaging inserts for your fragile product line or want them for your kits and subscription business, you’re in the right place. Hang on tight as we discuss the different packaging insert options available for every product type. You’ll also discover various promotional inserts your brand can consider for added engagement and upsell opportunities.

Packaging Insert Types

Packaging inserts can be either box inserts or promotional inserts. The first type supports a product’s protection and safety, while the second type serves as multi-purpose advertisement cards.

Box Inserts

Some of the immediate benefits of box inserts include:

- Effective blocking (preventing side-to-side movement) and bracing (preventing up-and-down motion) of one or several items in your box, reducing or eliminating the shock and resulting damage your products can acquire during impact while the box undergoes storage, transport, and hand delivery

- Compartmentalizing items, preventing them from rubbing against each other

- Reducing labor involved in applying protective wrap or assembling loose void fills

- Improving product presentation, resulting in positive unboxing moments

Here are the most common packaging insert types you can choose from:

Corrugated carton

These corrugated carton inserts typically separate the product from the cardboard packaging‘s walls. Their fluting layer cushions and reduces shock acquired by the item in case of impact during storage, transport, or hand delivery.

Due to their thickness, these inserts aren’t suitable for small products and items or primary packaging with complex shapes. Like paperboard inserts, the white paper variety is ideal for colored printing, while the Kraft paper type can take black-and-white printing. Learn more about the distinction with our guide comparing cardboard vs corrugated cartons.

Chipboard

Several recycled paper sheets glued and pressed together compose chipboard or particle board inserts. They’re thinner than corrugated boards and have no flutes, making them more appropriate for lightweight and non-fragile items. Like corrugated inserts, chipboards make great inlays, dividers, and pads for stacked items.

Paperboard

Paperboard may be thinner than corrugated cartons, but that’s what makes them versatile. You can easily fold and customize them into your desired shape and size. Solid bleached sulfate (SBS) for high-quality colored print and unbleached brown or Kraft paper for black-and-white printing are the most common paperboard options. They’re also the most inexpensive insert type and partner well with your paper box. Dig into more detail with our ultimate guide to custom packaging inserts.

Molded or paper pulp

Box makers combine recycled paper and cardboard to produce paper pulp inserts, which they mold into various shapes and sizes to secure glassware, electronics, ceramics, and other delicate products. Traditional egg carton boxes and many wine packaging use this insert type.

Mushroom packaging

Another highly recommended eco-friendly insert is mushroom packaging. The material consists of mycelium—the root system of mushrooms—and hemp hurd, or the inner fibers of a hemp stalk. Its insulating properties make it advisable for edible and temperature-sensitive goods.

Foam

Foam is lightweight and custom-cut to snugly fit a product’s specific shape. As a result, it’s another cushioning and protective option for fragile items.

Foam inserts come in low (cross-linked polyethylene or XLPE), medium (expanded polyethylene or EPE), and high densities (ethylene-vinyl acetate or EVA, resembling yoga mat material). Meanwhile, the soft and flexible polyurethane foam (which resembles the material used in dishwashing sponges) comes in various densities.

Molded plastic

Plastic is another customizable material available in various thicknesses and materials. The most popular are polyvinyl chloride and polyethylene terephthalate (made from recycled polymer used for food products).

Blister insert is the other name of this insert type, referring to the product of thermoforming or heat application to mold the plastic.

Here’s a summary of box inserts and the products they match with the best:

|

Material

|

Types/Options

|

Product weight

|

Fragility Level

|

|

Paper

|

Corrugated carton

|

Medium to heavy

|

Fragile

|

|

Chipboard

|

–

|

–

|

|

Molded or paper pulp

|

–

|

–

|

|

Paperboard

|

Light

|

Non-fragile

|

|

Plant fibers

|

Mushroom inserts

(but needs adequate ventilation and should avoid excessive moisture)

|

Light to medium

|

Fragile

|

|

Foam

|

Cross-linked polyethylene or XLPE

|

Light to medium

|

Fragile (for “class A surfaces” because it’s non-abrasive, including light objects such as smartphones and medium to heavy automotive parts)

|

|

Expanded polyethylene or EPE

|

Medium to heavy

|

–

|

|

Ethylene-vinyl acetate or EVA

|

Heavy

|

Fragile

|

|

Polyurethane

|

Light

|

Fragile

|

|

Plastic

|

Polyvinyl chloride or PVC

|

Light to medium

|

Fragile (food items, prescription medicine)

|

|

Polyethylene terephthalate or PET

|

–

|

–

|

Promotional Inserts

Promotional inserts or insert cards can take various forms depending on your brand, product, and target audience. Here are some ideas to inspire you:

Thank you card

Buyers feel valued when businesses appreciate their interest and loyalty through thank-you cards. The gesture allows startups and small businesses to build relationships and spread a positive impression of their brand.

Handwritten, personalized messages with the customer’s name make them feel extra special and can result in up to a 7% boost in conversion.

John Cronin is known for sending a handwritten appreciation for every purchase of his John’s Crazy Socks. Cronin, who has Down syndrome, co-founded the business with his father, Mark, back in 2016.

Coupon or discount offer

With inflation on the rise, 90% of consumers look for discounts and cash backs. Thus, money-saving promos can encourage repeat purchases and customer retention. Including inserts within packages also help ensure that your buyers can view and consider the offer instead of it just ending up in their email spam folder.

You can grant discounts based on your clients’ minimum spend (a specific percentage or dollar amount off). Recent Statista data shows that over half of consumers prefer percentage discounts. Other options include organizing a contest or setting a period for claiming products at a reduced price.

Boxy Charm used inserts to announce its one-day discount for its beauty subscription business clients.

You may also consider collaborating with another business with a complementary product or service for a joint or cross-promotional offer.

Social share/product review request

These inserts can effectively continue engagement with your customer beyond the arrival of their order.

Give them a reason to connect with and follow your social channels by requesting online feedback about their purchase.

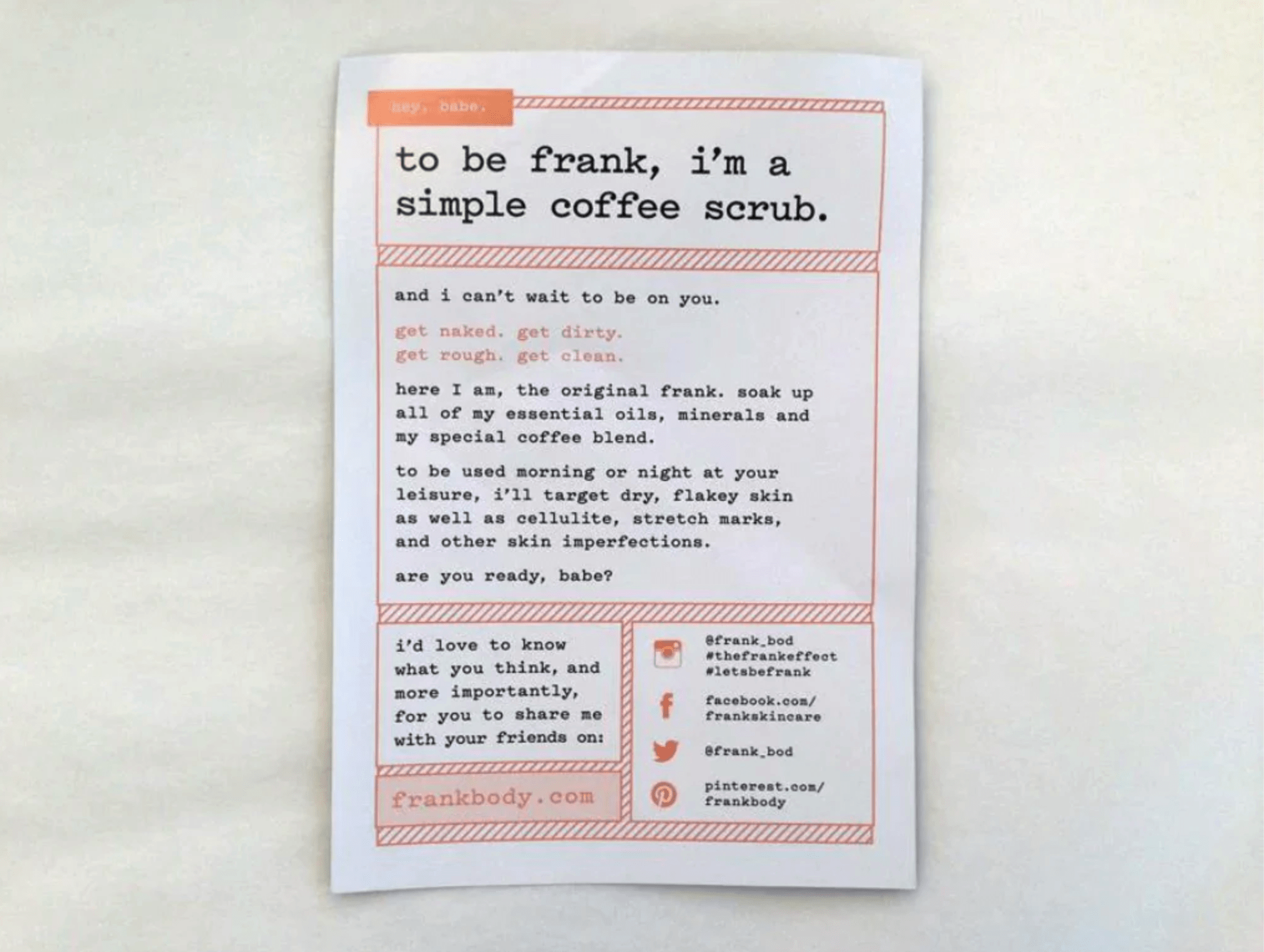

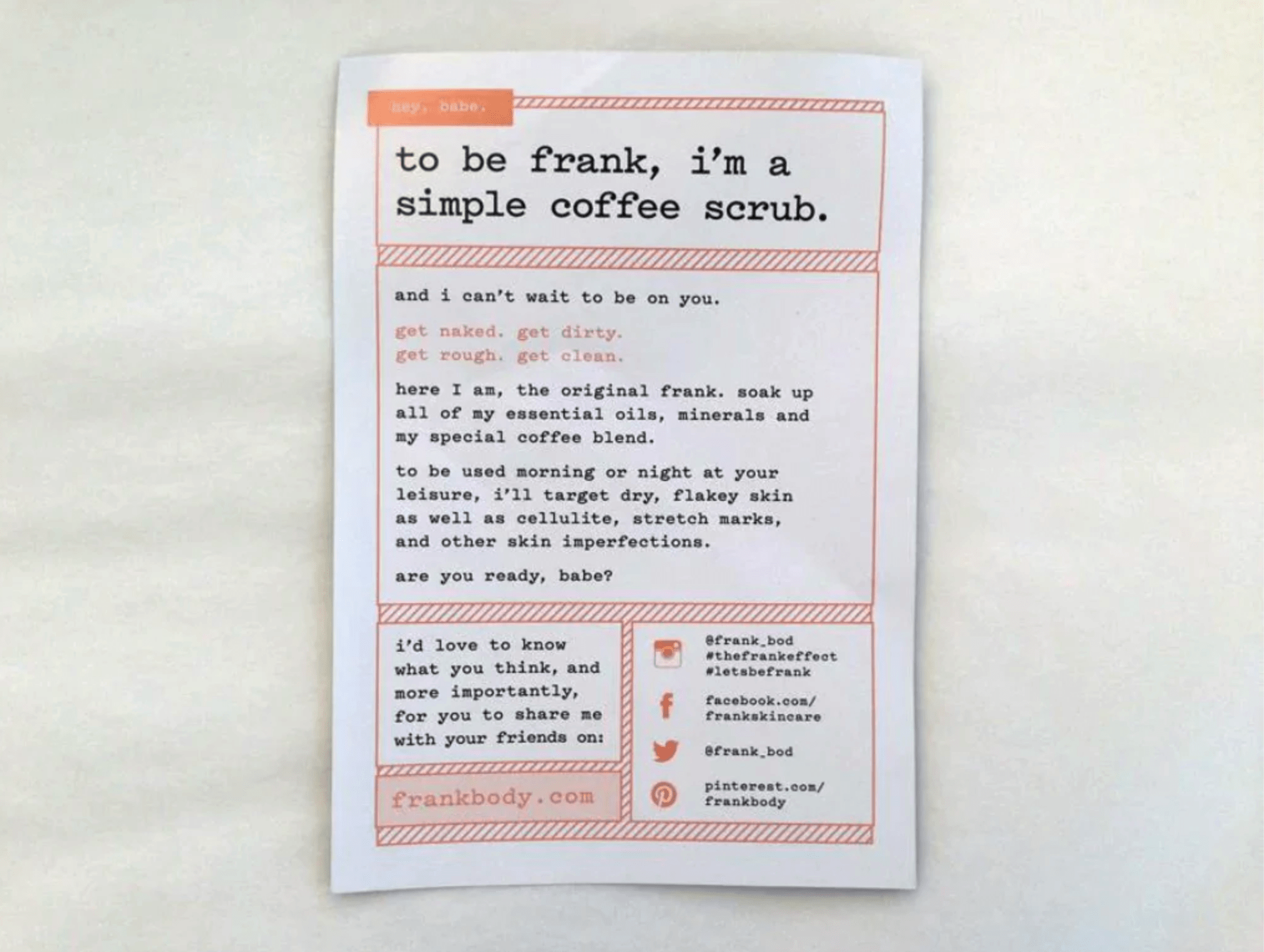

Frank Body used personification in its social media share insert, with its coffee body scrub encouraging users to connect with the skincare company on social media.

To make the review process easier, list the social links and questions you’d like them to answer. Moreover, you can add a QR code that takes buyers to a landing page containing the review form. You may also include a QR code that will direct them to a newsletter sign-up form so they can get regular updates on your new products and bargains.

Referral card

Do you know that 40% of consumers trust referral marketing? You can turn your shoppers into your extended marketing team through referral cards that will reward them and their friends with discounts or freebies. Make your referral inserts look like invites or business cards to make “customer recruitment” enticing and fun.

Stickers

Who doesn’t love freebies? Make customers feel proud about being part of your brand community by inserting stickers they can apply on their laptops, on the back of their phones, and on other surfaces. Stickers can also expand public awareness of your business.

Warranty guide

Make your product warranty registration and process less boring by having your box manufacturer produce custom warranty inserts.

Scooter brand Micro has a warranty card, which points new owners to its website for activation and further details.

Usage and care instructions

Consider including this insert type if customers must follow steps to properly and safely use, clean or wash, and store your products.

Your product’s ingredients and warnings—such as possible allergic reactions and emergency first-aid advice—are other content you can include in instruction inserts.

Naples Olive Oil’s gift set includes recipe cards for using the oil, balsamic vinegar, and dipping spice blend in the box.

Interactive elements

Your insert can feature a fun puzzle, brainteasers, DIY activities, and additional tips for using your product. Smart content—such as scannable augmented reality (AR) codes showing your company’s history, “behind-the-scenes” footage, or games—also provides memorable experiences. Nine out of 10 brands say they plan to incorporate AR in their marketing campaigns.

Custom Die-Cut Inserts: Production Process

Inserts can be as simple as paperboard and corrugated carton dividers that offer multiple partitions for objects, such as glass bottles, coffee K-cups, and others.

But for custom inserts, box makers use die-cut machines with multiple cutters and blades to create inserts based on your product’s shape. They add cut-outs, slots, and holes, so you or their team can slip and fold without needing extra tools.

Packaging companies can also add color printing or custom-printed copy on carton inserts to further professionalize your packaging’s appearance. Customizations include:

- Embossing or raising an image or design on the box surface.

- Debossing—the opposite of embossing—involves sinking the design into the box surface.

- Spot UV coating or applying a clear coating that results in a high gloss or sheen.

- Foiling or applying thin metal (gold, silver, aluminum, or copper) foil to the box surface.

How to Choose the Proper Insert for Your Packaging

Box Insert

Determining the right box insert for your product will involve the following steps:

1. Note your product’s dimensions and weight

Consider your item’s length, width, height, thickness, or diameter plus its weight when deciding what insert to use. Heavier products will naturally need tougher materials to support them.

2. Establish how much protection your item requires

Pastry and flowers need a different kind of protection compared to glass and ceramics. Your shipping and handling method will also affect your material selection. Foam and molded pulp are the most typical choices for products with primary packaging, which can break or sustain scratches and dents.

3. Review your budget

Your budget will determine the materials you can choose from. Ask your packaging designer or box supplier how they shock-proof your product if you prefer lighter, or lower-density materials, especially if you want to reduce your shipping expenses.

However, the best practice is to follow courier suggestions for packaging to ensure your box and its contents can survive hazards like poor weather, accidental drops, and poor road conditions.

4. Study your packaging’s environmental impact

The latest U.S. Environmental Protection Agency report citing 2018 data showed that 82 million tons of solid waste came from containers and packaging. In the EU, cardboard and paper contributed to 32.7 million tons of waste from 2009 to 2020, while plastic and glass came in second and third, with waste amounting to around 15 million tons each.

In light of these saddening figures, using biodegradable, compostable, and recyclable materials reduces pollution and can enhance your brand image. Paperboard, pulp, and mushroom inserts are the most sustainable choices. If you must choose heavier, less recyclable materials, promote your packaging’s re-use opportunities.

Promotional Insert

Discovering what promotional insert must go with your product depends on your:

1. Goals

Choose the insert type that will fulfill your business needs, which may be more customers, increased sales, introduction of a new product, or awareness of your online platforms.

2. Customer base

You can segment your clients and send personalized inserts based on where they are in the customer journey. For instance, a thank you card and an insert that tells your brand story are fitting for new customers. Meanwhile, discount coupons or loyalty program invitations can excite your regular shoppers.

3. Budget

Set your marketing budget first to see how much you can spend on materials, type of printing, special coating, or interactive tech additions.

Fragile Items That Benefit from Box Inserts

Chipboard, corrugated, and foam inserts can protect these delicate items that are at risk of damage during shipping:

- Electronics: smartphones, laptops, TV sets, computer monitors

- Glass: glassware, stemware (drinkware that stands on stems), vases, mirrors

- Ceramics: bowls, plates, figurines

- Artwork: paintings, photographs, sculptures

- Musical instruments: flutes, violins, guitars

Producing Inserts for Medication

For medication boxes, the U.S. Food and Drug Administration (FDA) has specifications for patient package inserts (PPI), which it considers a labeling method for patients and caregivers. According to its website, PPI must include information about the medicine, how to take it, common and serious side effects, and who should not take the medicine.

Except for oral contraceptives and medicine with estrogen, brands may voluntarily submit medication PPI to the FDA “on their initiative or by FDA request.”

Choose a Sustainable Custom Packaging Company for Your Customized Inserts

Read our A-Z guide to packaging definitions to help you get up to speed with industry terminology as you create your own custom boxes.

Packaging firms typically specialize in only a few materials for their custom packaging inserts so you must check if your supplier can produce the type needed for your mailer box, marketing kit, and subscription boxes.

Refine Packaging can customize box inserts for various products. Cardboard, corrugated, and foam options are available. We don’t make plastic inserts. Contact us for any questions or concerns about your planned box insert so we can help you arrive at a solution that will upgrade your packaging box’s sales potential.

.svg)

Share