Corrugated packaging is everywhere.

More than 95% of all goods consumed in North America are packaged and transported in corrugated packaging. Corrugated boxes are universal – both at work and at home. A true staple of the retail world.

But what exactly is corrugated packaging? Why is corrugated material so commonly used? And when should corrugated packaging be used?

What is Corrugated Packaging?

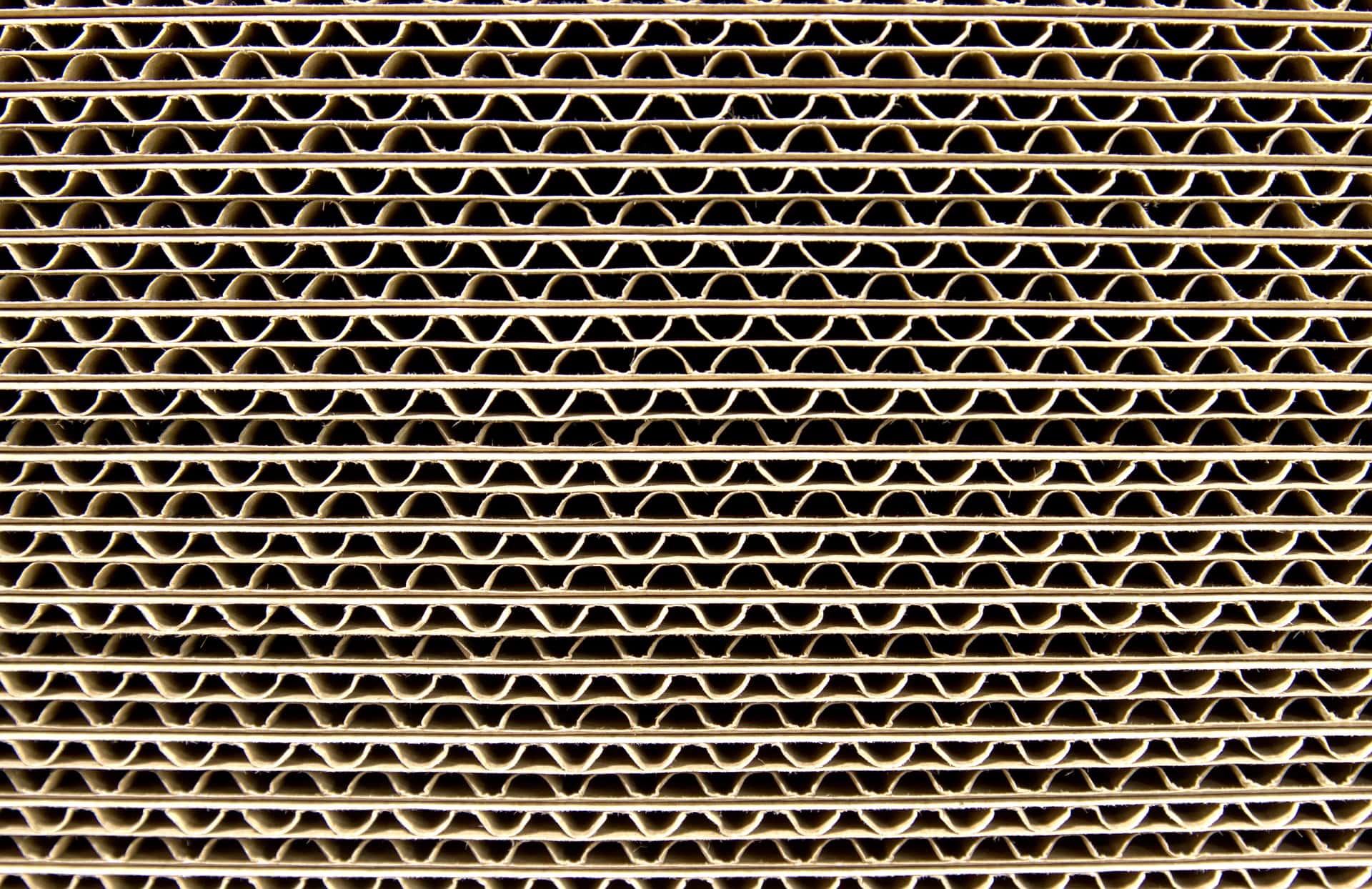

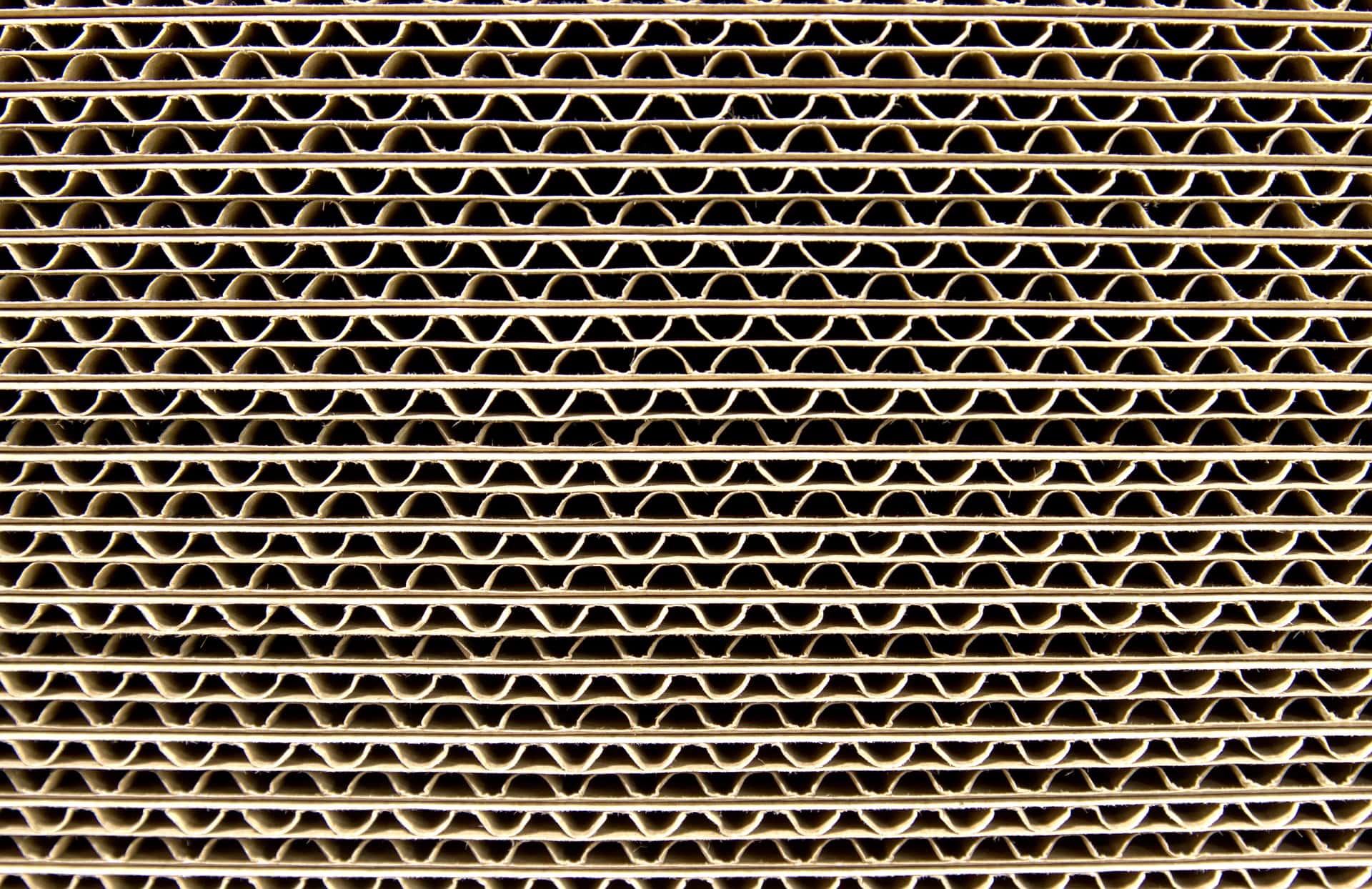

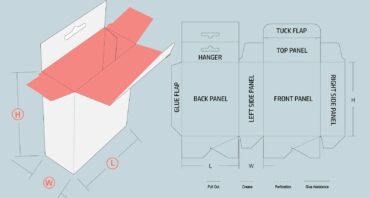

Corrugated packaging is a durable, cost-effective, and versatile packaging material that’s made from 3 or more sheets of corrugated fiberboard (also known as container board). Corrugated boxes are made from a flat material called linerboard and a medium, which is paper that’s formed into flutes and glued between linerboard.

Who Invented Corrugated Packaging?

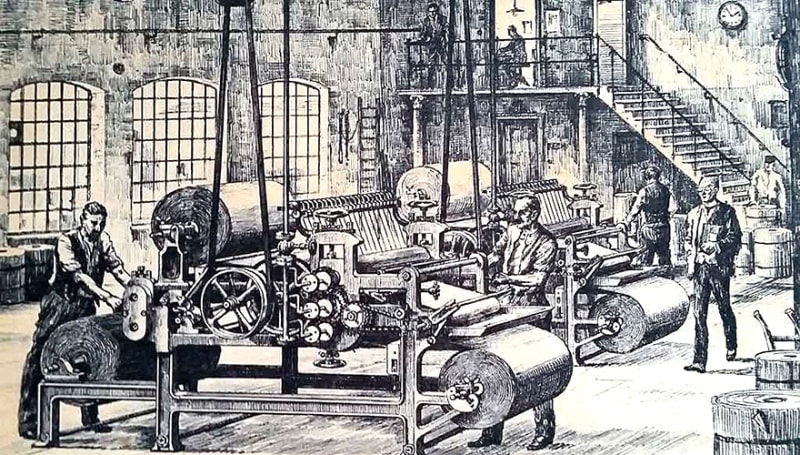

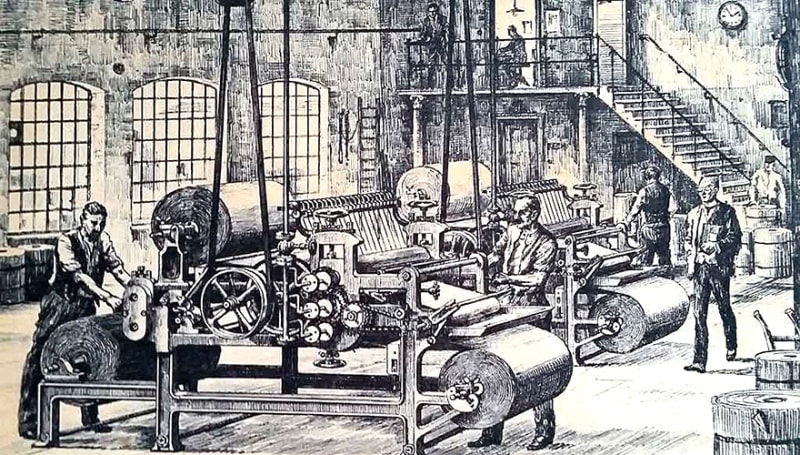

Corrugated packaging as we know it goes back more than a century, born from the need to package and store goods for a longer period of time.

In 1856, Healey and Allen, two Englishmen, secured a patent for the first known use of corrugated paper. Using two fluted rolls, corrugated paper was fed through a hand-cranked machine, creating fluted paper lining that could be placed in hats.

But corrugated paper for hats is one thing, and corrugated packaging for transporting products is completely different. An American named Albert S. Jones is responsible for this combination, and was the first person known to use corrugated paper to wrap fragile items like bottles and other easily breakable goods in a similar way that corrugated packaging is used today.

How is Corrugated Packaging Made?

The process for creating corrugated packaging hasn’t changed much since its humble origins in the 1850s.

With corrugated packaging, two sheets of flat paper known as liners or linerboard, are glued to a corrugated inner material called fluting.

Together, these distinctive layers are stronger than they would be if they were used separately. If you look closely at corrugating packaging, you can see a type of weave pattern. This is what adds structure and stability to the packaging.

Different fluting can be used to make different sizes of arch in the material, creating an end result that is structurally superior to many other types of packaging and is a great option for products that need to be handled and packed carefully.

Curious for more details? We dive deeper into the corrugated packaging process and different flute grades in our ultimate guide to corrugated packaging.

Why Use Corrugated Packaging?

There are several reasons why you might consider using corrugated packaging as your product packaging of choice:

There are several reasons why you might consider using corrugated packaging as your product packaging of choice:

- Stronger than Cardboard: Safe, sturdy and protective, corrugated boxes are stronger than cardboard, so you can feel confident that whatever you put inside will stay safe and sound. Corrugated packaging is also crush and pressure-resistant.

- A Wide Range of Sizes: Corrugated packaging is available in a wide range of sizes. Although it’s strong, it’s also lightweight, making it a great fit for nearly any type of product that needs to be protected, but without the added weight.

- Can Be Broken Down and Reused: Corrugated boxes can be broken down and stored easily or transported without affecting the structural integrity of the packaging.

- Good for the Environment: The packaging material itself is made from recycled and renewable materials, such as Kraft, making them an eco-friendly packaging option that consumers will appreciate.

Corrugated vs. Cardboard Packaging: What’s the Difference?

With the incredible surge in online shopping (COVID19 notwithstanding), customers expect their packages to be delivered safe and sound, with the contents in good condition.

Packages that arrive damaged, crushed, or torn open leave a bad impression when unboxing. That’s why it’s so important to consider what level of strength and stability you need in your packaging.

Corrugated packaging and cardboard packaging are two of the most popular types of boxes, but it’s important to understand the difference between them so you can decide on the right balance of protection for the product inside.

Cardboard Packaging

Cardboard, also known as carton packaging, is made from thick paper or paper pulp which is then crafted into small packages or even material to help bolster the structure of lesser materials so that the contents won’t lose their shape.

Cardboard is inexpensive and easy to use as part of most shipping strategies, but it also may need additional packing material to keep the contents safe from being crushed, or being damaged by the elements.

Corrugated Cartons

These are made up of several layers of material that are stronger together than they would be on their own. An inside liner and an outside liner are filled in the middle with a fluted material that helps solidify and strengthen the entire piece.

Corrugated cartons perfectly balance strength and lightness of weight, so they’re perfect if you need to ship a variety of products carefully. In addition to their structural strength, they’re also resistant to moisture and sudden changes in temperature.

Of course, no container is fully impervious to being crushed or being exposed to rain, sleet or heat for a long period of time, but if you want the added confidence that your product will arrive securely, corrugated packaging is a great option.

Learn more about folding cartons with our ultimate guide to carton packaging to better understand the differences between corrugated and cardboard.

When To Use Corrugated Packaging

Corrugated packaging is best for products that need to be transported from a warehouse, to a processing center and onto a delivery vehicle. With so many people and machines handling the package, it needs to withstand being shuffled, slid, tossed and even dropped. If you want to add in an extra barrier of protection, you can wrap the interior product with additional cushioning for added security and peace of mind.

Corrugated boxes are also a great choice if you want full customization control over your packaging design. You get all of the benefits of a large design area like with cardboard, except the added strength and durability. Additional features like custom opening folds, flaps, die-cuts and embossing or debossing are just a few of the many options you can add to create a unique design without worrying that the process will mar the product within.

If you’re selling food, corrugated packaging is a must. Not only is corrugated much more sustainable and hygienic, but with so many people turning to online grocery shopping and delivery, companies are choosing to insulate their corrugated packaging for even greater protection to help seal in the temperature, especially for perishable goods.

Choose a Trusted Corrugated Packaging Box Manufacturer

Read our packaging terms guide to help you get up to speed with industry terminology as you create your own custom boxes.

At Refine Packaging, our decades of combined experience, coupled with our deep knowledge of the custom packaging process across a variety of industries allow us to provide you with full-service packaging design and printing services.

From choosing the right packaging material for your product, to designing a look that captivates your audience and elevates your brand, trust the professionals at Refine Packaging to deliver an end result that’s so powerful and so compelling, you’ll want to buy your own product!

If you’re interested in learning more about how corrugated packaging may be the right choice for your packaging and shipping and fulfillment needs, or you’d like to consult with us on crafting the perfect design to showcase your product, we’d be delighted to work with you.

Even if you’re not sure what type of packaging you need for your product, get in touch with us. Our experts will take the time to understand your vision and your needs and work with you to craft packaging that perfectly expresses all of those points in one artistic creation.

Contact us today to learn more about our extensive printing and packaging services and get a free, no obligation quote for all your custom packaging needs.

There are several reasons why you might consider using

There are several reasons why you might consider using

.svg)

Share