Die cutting is used in the printing and packaging industry to refer to the cutting out of different shapes using machinery.

With die cut printing, it’s possible to specify exact measurements and have the machine cut them to exact dimensions every time.

As you might imagine, this precision is extremely useful for product packaging design, where you need to create a consistent and professional look each and every time.

What is Die Cutting?

Die cutting is a manufacturing process where a die is customized through cutting, forming or shearing to craft a desired shape, design or pattern. Die cut printing is used in the packaging process to correctly cut, ship and print according to specific measurement specifications, as outlined in a dieline.

What is a Die?

Die cuts start with a die, which is a metal object that has sharp areas for cutting.

A die resembles cookie cutters in that the shape that the metal object is designed will be the same shape that’s cut in the material. There are several kinds of dies. For example, steel-rule dies are very sharp, but are protected with plastic or foam for safety.

Steel-rule dies are made to cut thicker packaging materials, or to cut a stack of less-thick packaging all at once. There are also thinner metal dies, which aren’t as sharp and can’t cut very thick material. These types of dies are lighter in weight and easier to store, and also don’t have foam or plastic around them for safety.

Manual and Digital Die Cutting Machines

Die cutting takes place with both manual and digital die cutting machines. Manual die cutting machines use a crank that is turned in order to cut the material. The metal die passes through the machine’s rollers and uses that pressure to help cut the shape out of the paper based on the shape of the die. Manual die cutting machines may also have motors that help to apply this pressure.

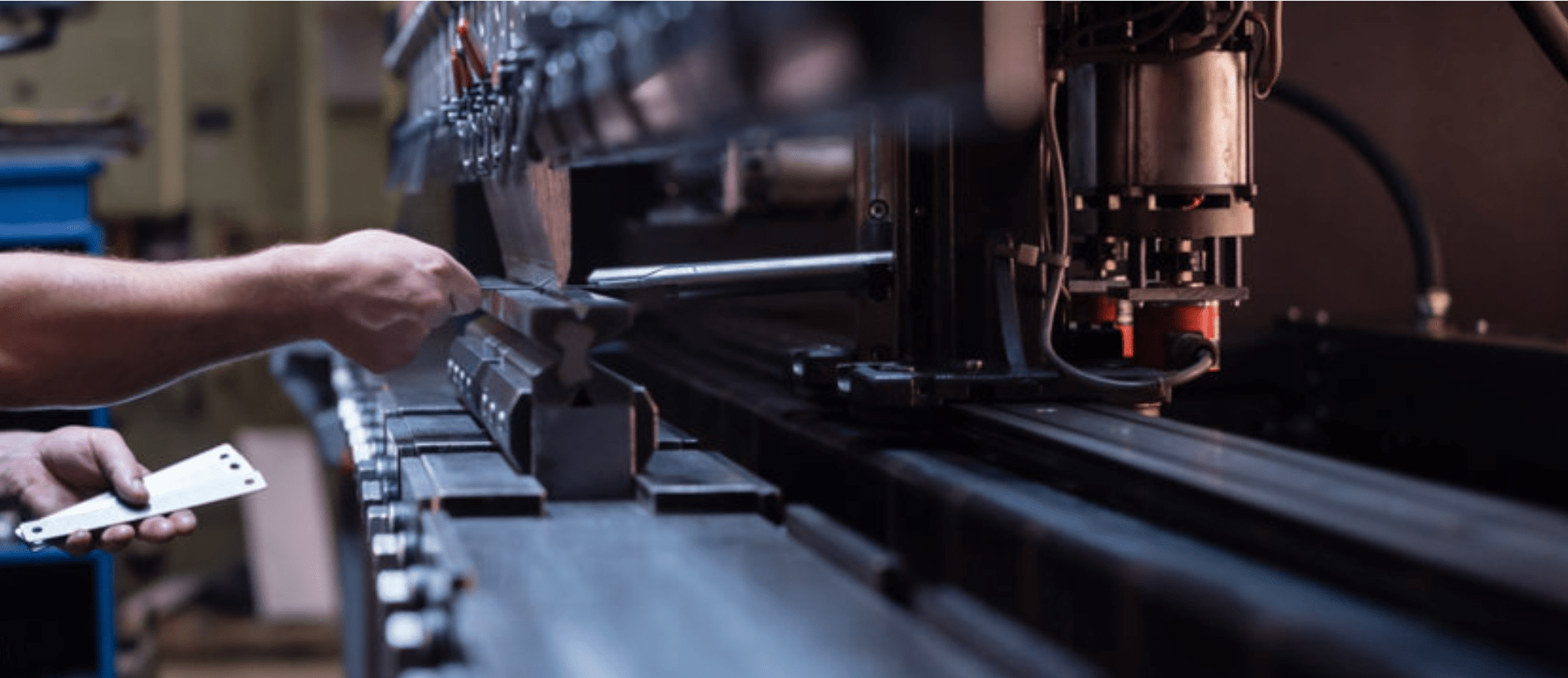

Digital die cutting machines are generally controlled by software. They do not require steel dies because there’s a blade within the machine that cuts the shape. The software is used to select that shape and it can be created via computer, phone, tablet or even a specialized cartridge that the machine uses.

Die Cut History: Why is it Called Die Cutting?

The origin of the phrase die cutting comes from the 1300s, from the middle English word ‘de’, believed to be from the Latin word “datum” for “given”, as well as put or placed.

The root meaning of die cutting is to place or cast. Back in the 1300s, dies were primarily used to cast or stamp metal coins.

It wasn’t until the 1800s that the mass-production of items of a similar size and shape took off, and this old term “die” was used to specify that it was “created by machines”.

Cut refers to creating a custom shape, and die cutting means the casting and cutting of shapes.

The term die cutting was not commonly used until the 1800s, when it was meant as a method for creating more precise and accurate shoe sizes. Since shoes were made of leather, the soles had to be cut by hand, which was a tedious process that often led to errors and ill-fitting shoes.

When the die cutting machine was invented, this meant that shoes could now have standard sizes (something we often take for granted today).

The Role of a Dieline in the Custom Die Cut Process

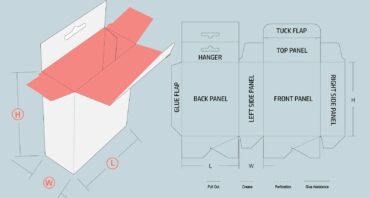

Before you make a die cut on any printed material, you’ll want to first have an outline of what needs to be cut. This is where a dieline comes into the custom die cut process.

Dielines are part of die cut printing, and are used to outline the shape and packaging box size before any cutting happens.

With so many different shapes possible in the packaging world, if you can dream it, chances are a custom packaging manufacturer can make the material into any cuttable shape.

If you still need to make a dieline, read our guide about what a dieline is to learn more about how to make a dieline for your packaging and printing project. Remember, you’ll need a dieline before you can get to the finishing touches of your packaging like matte and gloss lamination, embossing and debossing or UV coating.

Considerations for Different Types of Die Cutting Processes

There are different types of die cutting processes. The one used for your project will depend on your specific needs and your vision for your product. Some of the more popular methods include:

- Blanking: Blanking takes flat material and slices it by clipping it from the outside edge, which makes it look even more flat.

- Drawing: Drawing pulls material through the machine to a specific length. It is typically used for products that are thin and/or long.

- Forming: Forming happens when the raw material is shaped on a curved surface. It is generally used together with your drawing to create cylindrical parts of your custom packaging.

- Coining: With coining, circular holes are made in the material by adding pressurized force to them. This creates a very intricate look in packaging.

- Broaching: Multiple rows of “teeth” are used to cut material that the steel die cannot otherwise cut using the broaching method.

There are many other types of die cutting out there in both digital and offset printing, but this will give you an idea of the types most often used in packaging.

Beyond the types of die cutting, there are also different die cutting services depending on your needs. For instance, flatbed die cutting, also known as steel rule die cutting, uses a flatbed die cutting press and custom dies to create its custom shapes (dies). It’s ideal for thicker material, larger components of packaging or even short production runs.

For higher volume production runs, there’s rotary die cutting which uses cylinder-shaped dies to convert flexible material into custom boxes or packaging. This is ideal for high-volume runs as well as designs that need exact accuracy.

There’s also digital die cutting, which doesn’t use dies at all. Instead, it uses lasers, blaces and tool bits to score, crease and cut the material. This type of die cutting is best used for applications that need fast lead times, but still require high levels of precision.

Can I Make My Own Metal Dies?

Although you technically can make your own metal dies by welding different pieces together, it is not recommended. In this case, it’s best to leave the die cutting, as well as the shaping and forming of dies, to the printing and packaging experts.

If you have an unusual shape in mind for your custom packaging, it’s best to let us create the metal die for it, since this way we can be certain that it will work with our specialized machines.

What Are Cutting Pads or Plates?

Cutting plates, also known as cutting pads, create a sort of “die cut sandwich” of all of the components and materials needed to make your packaging design happen. The “sandwich” is the type of packaging, the design and more so that the end result comes out looking exactly the way you envisioned.

Think of it as a similar process as putting a cookie cutter through dough to create your ideal shape which you can then decorate. Die cutting is a similar process through the use of cutting pads or plates. Over time, these pads or plates need to be replaced because they can wear down.

Curious to learn more? Our comprehensive A-Z guide to packaging definitions can help you get up to speed with industry terminology as you create your own custom boxes.

Using Die Cutting and More to Create Your Packaging

As you can see, die cutting is a very versatile way to accurately cut, shape and print your packaging so that the end results can be duplicated again and again without room for error. Not only is die cutting precise, but it also allows you a great deal of freedom with your retail packaging.

Still, we understand that not everyone is a packaging and printing expert. Fortunately, at Refine Packaging, we are. We’d be happy to answer any questions you may have about the die cutting process or how it will work with your product packaging vision.

If you have an idea in mind, but aren’t sure how to make it a reality with regard to your product packaging, don’t worry. We have a team of phenomenal artists and engineers that can turn your vision for your carton boxes, corrugated boxes or other branded packaging into a stunning, eye-catching reality.

We invite you to contact us to request a free quote about our packaging and printing processes as well as our packaging design options to help determine the best way forward for your unique design. There has never been a better time to make your product come to life than with the knowledgeable experts at Refine Packaging.

.svg)

Share